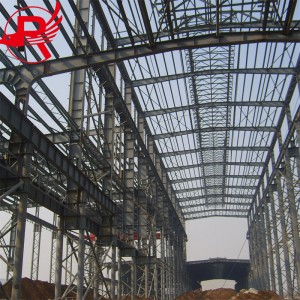

מבנה פלדה עם מבנה פלדה למגורים ישים

מבנה פלדה טרומיהוא מבנה פלדה המורכב מחומרי פלדה והוא אחד מסוגי מבני הבנייה העיקריים. המבנה מורכב בעיקר ממבנה פלדה, עמודי פלדה, קורות פלדה ורכיבים אחרים העשויים מפלדת חתך ולוחות פלדה, ומאמץ סיליניזציה, פוספטציה של מנגן טהור, שטיפה וייבוש, גלוון ותהליכים אחרים למניעת חלודה.

*בהתאם ליישום שלך, אנו יכולים לתכנן את מערכת שלדות הפלדה החסכונית והעמידה ביותר כדי לעזור לך ליצור ערך מקסימלי עבור הפרויקט שלך.

| שם המוצר: | מבנה מתכת של בניין פלדה |

| חומר: | Q235B, Q345B |

| מסגרת ראשית: | קורת פלדה בצורת H |

| פורלין: | פורלין פלדה בצורת C, Z |

| גג וקיר: | 1. יריעת פלדה גלית; 2. פאנלים מצמר סלעים; 3. פאנלים מבד EPS; 4. פאנלים מצמר זכוכית |

| דֶלֶת: | 1. שער מתגלגל 2. דלת הזזה |

| חַלוֹן: | פלדת PVC או סגסוגת אלומיניום |

| פיה למטה: | צינור PVC עגול |

| יישום: | כל מיני סוגים של סדנה תעשייתית, מחסן, מבנים רבי קומות |

תהליך ייצור המוצר

יִתרוֹן

נוקשות מספקת

נוקשות מתייחסת ליכולתו שלסדנת מבנה פלדהכדי להתנגד לעיוות. אם רכיב הפלדה עובר עיוות מוגזם לאחר שהופעל עליו עומס, הוא לא יפעל כראוי גם אם לא ניזוק. לכן, רכיב הפלדה חייב להיות בעל קשיחות מספקת, כלומר, אסור שבר קשיחות. דרישות הקשיחות שונות עבור סוגים שונים של רכיבים, ויש להתייעץ עם תקנים ומפרטים רלוונטיים בעת יישום.

יציבות מתייחסת ליכולתו של רכיב פלדה לשמור על צורת שיווי המשקל המקורית שלו תחת פעולת כוח חיצוני.

אובדן יציבות הוא תופעה שבה רכיב פלדה משנה לפתע את צורת שיווי המשקל המקורית כאשר הלחץ עולה במידה מסוימת, מה שמכונה חוסר יציבות. חלק מהרכיבים הדחוסים בעלי דופן דקה עלולים גם הם לשנות לפתע את צורת שיווי המשקל המקורית שלהם ולהפוך לבלתי יציבים. לכן, רכיבי פלדה אלה צריכים להיות בעלי יכולת לשמור על צורת שיווי המשקל המקורית שלהם, כלומר, יציבות מספקת כדי להבטיח שלא יהיו יציבים וינזקו בתנאי השימוש שצוינו.

חוסר היציבות של מוט הלחץ מתרחש בדרך כלל פתאום והוא הרסני מאוד, ולכן מוט הלחץ חייב להיות בעל יציבות מספקת.

לסיכום, על מנת להבטיח עבודה בטוחה ואמינה של רכיבי פלדה, עליהם להיות בעלי כושר נשיאה מספיק, כלומר, חוזק, קשיחות ויציבות מספקים, שהן שלוש הדרישות הבסיסיות להבטחת עבודה בטוחה של רכיבים.

ייצור מתכת הוא יצירת מבני מתכת על ידי תהליכי חיתוך, כיפוף והרכבה. זהו תהליך בעל ערך מוסף הכרוך ביצירת מכונות, חלקים ומבנים מחומרי גלם שונים.

ייצור מתכת מתחיל בדרך כלל בשרטוטים עם מידות ומפרטים מדויקים. מפעלי ייצור מועסקים על ידי קבלנים, יצרני ציוד מקורי (OEM) וספקי בדיקות ערך (VAR). פרויקטים אופייניים כוללים חלקים רופפים, מסגרות מבניות לבניינים וציוד כבד, מדרגות ומעקות.

בניית מוצר

מחסן מבני פלדההוא מבנה המורכב מחומרי פלדה והוא אחד מסוגי מבני הבנייה העיקריים. המבנה מורכב בעיקר מקורות פלדה, עמודי פלדה, מסבכי פלדה ורכיבים אחרים העשויים מפלדה מעוצבת ולוחות פלדה, ומאמץ תהליכי הסרת חלודה ונגד חלודה כגון סיליניזציה, פוספטציה של מנגן טהור, שטיפה וייבוש וגלוון. כל רכיב או רכיב מחוברים בדרך כלל באמצעות ריתוכים, ברגים או מסמרות. בשל משקלו הקל ובנייתו הפשוטה, הוא נמצא בשימוש נרחב במפעלים גדולים, אתרי תיאטרון, בנייני קומות רבי קומות, גשרים ותחומים אחרים. מבני פלדה נוטים לחלודה. באופן כללי, מבני פלדה צריכים לעבור הסרת חלודה, גלוון או צביעה, ויש לתחזק אותם באופן קבוע.

בַּקָשָׁה

מפעל מבני פלדההוא מבנה המורכב מחומרי פלדה והוא אחד מסוגי מבני הבנייה העיקריים. המבנה מורכב בעיקר מקורות פלדה, עמודי פלדה, מסבכי פלדה ורכיבים אחרים העשויים מפלדה מעוצבת ולוחות פלדה, ומאמץ תהליכי הסרת חלודה ונגד חלודה כגון סיליניזציה, פוספטציה של מנגן טהור, שטיפה וייבוש וגלוון. כל רכיב או רכיב מחוברים בדרך כלל באמצעות ריתוכים, ברגים או מסמרות. בשל משקלו הקל ובנייתו הפשוטה, הוא נמצא בשימוש נרחב במפעלים גדולים, אתרי תיאטרון, בנייני קומות רבי קומות, גשרים ותחומים אחרים. מבני פלדה נוטים לחלודה. באופן כללי, מבני פלדה צריכים לעבור הסרת חלודה, גלוון או צביעה, ויש לתחזק אותם באופן קבוע.

בדיקת מוצר

ב-מבנה פלדה למחסןפרויקט פיקוח, פריטי הפיקוח העיקריים הם כדלקמן:

ראשית, בדקו את גודל הרכיבים ואת שטוחותם.

שנית, זיהוי פגמים פני השטח של רכיבים

שלישית, לזהות את החיבור (ריתוך, ברגים)

רביעית, לזהות את עובי הציפוי מעכב האש

חמישית, גילוי קורוזיה של מוט פלדה

מדדו כל ממד ב-3 חלקים של הרכיב, וחשבו את הממוצע של 3 המיקומים כערך מייצג של הממד. יש לחשב את סטיית הממדים של חלקי הפלדה על סמך הממדים שצוינו בשרטוטי התכנון. הערך המותר של הסטייה צריך לעמוד בדרישות תקני המוצר.

פּרוֹיֶקט

החברה שלנו הקימה זה עתה פרויקט מפעל למבני פלדה בשנת 2023. להלן פרטי הפרויקט.

אחסון קירור עילי: המבנה הוא מחסן מבנה פלדה חד-שכבתי עם שטח בנייה של 6307.33 מ"ר. אחסון קירור דרומי: המבנה הוא מחסן מבנה פלדה בן קומה אחת עם שטח בנייה של 8076.91 מ"ר. אחסון קירור צפון: המבנה הוא מחסן מבנה פלדה בן קומה אחת עם שטח בנייה של 7334.65 מ"ר. 2# מפעל צרפתי: המבנה הוא מבנה מסגרת פלדה פורטלית, עם קומה אחת מעל הקרקע וחלק שתי קומות, עם שטח בנייה של 25923.11 מ"ר. חדר דוודים: המבנה הוא מבנה מסגרת בטון מזוין עם שטח בנייה של 2480.08 מ"ר. 3# מחסן מיזוג אוויר: המבנה הוא מבנה מסגרת פלדה פורטלית עם קומה אחת מעל הקרקע ושטח בנייה של 28001.11 מ"ר. 2# מחסן מיזוג אוויר: המבנה הוא מבנה מסגרת פלדה פורטלית, עם קומה אחת מעל הקרקע ושטח בנייה של 8075.81 מ"ר. סככת פחם: המבנה הוא מבנה שלד מבטון מזוין עם שטח בנייה של 4959.36 מ"ר. מתקן טיהור שפכים: המבנה הוא מבנה שלד מבטון מזוין עם שטח בנייה של 7672.05 מ"ר.

אריזה ומשלוח

יש לארוז מבני פלדה במהלך המשלוח כדי להגן על בטיחותם ושלמותם ולמנוע נזק ואובדן של הסחורה במהלך ההובלה. להלן הדרישות הבסיסיות לאריזת משלוח של מבני פלדה:

1. חומרי אריזה: יש להשתמש בחומרי אריזה מתאימים לאריזה. כולל עץ, לוחות עץ, לוחות פלדה, קופסאות פלדה, קופסאות עץ, משטחי עץ וכו', יש לוודא שחומרי האריזה בעלי חוזק וקשיחות מספקים.

2. הידוק אריזה: אריזות של מבני פלדה צריכות להיות מהודקות וחזקות, במיוחד פריטים גדולים. יש להתקין ולקבע אותן על משטחים או תומכים כדי למנוע תזוזה או רעידות במהלך ההובלה.

3. חלקות: מראה מבנה הפלדה חייב להיות חלק, ואסור שיהיו בו פינות או קצוות חדים כדי למנוע נזק לסחורות אחרות או סיכון הבטיחות האישית של העובדים.

4. עמידות בפני לחות, זעזועים ובלאי: חומרי אריזה צריכים לעמוד בתקנות השילוח ולהיות עמידים בפני לחות, זעזועים ובלאי. במיוחד במהלך הובלה ימית, יש לשים לב לעמידות בפני לחות, ייבוש, נייר עמיד בפני לחות וטיפולים אחרים כדי למנוע שחיקה, חלודה וקורוזיה של מבנה הפלדה על ידי מי ים.

חוזק החברה

תוצרת סין, שירות מהשורה הראשונה, איכות חדשנית, בעל שם עולמי

1. אפקט קנה מידה: לחברה שלנו שרשרת אספקה גדולה ומפעל פלדה גדול, המשיג אפקטים של קנה מידה בתחבורה וברכש, והופך לחברת פלדה המשלבת ייצור ושירותים.

2. גיוון מוצרים: גיוון מוצרים, ניתן לרכוש מאיתנו כל פלדה שתרצו, עוסקים בעיקר במבני פלדה, מסילות פלדה, יריעות פלדה, סוגריים פוטו-וולטאיים, פלדת תעלות, סלילי פלדת סיליקון ומוצרים אחרים, מה שהופך אותו לגמיש יותר. בחרו את סוג המוצר הרצוי כדי לענות על צרכים שונים.

3. אספקה יציבה: קו ייצור ושרשרת אספקה יציבים יותר יכולים לספק אספקה אמינה יותר. זה חשוב במיוחד עבור קונים הזקוקים לכמויות גדולות של פלדה.

4. השפעת מותג: השפעה גבוהה יותר של המותג ושוק גדול יותר

5. שירות: חברת פלדה גדולה המשלבת התאמה אישית, הובלה וייצור

6. תחרותיות מחירים: מחיר סביר

*שלחו את המייל אל[מוגן בדוא"ל]לקבלת הצעת מחיר לפרויקטים שלך

לקוחות מבקרים