ערימת יריעות פלדה בצורת Z מגולגלת קרה עם עצירת מים

גודל המוצר

| סָעִיף | רוֹחַב | גוֹבַה | עוֹבִי | שטח חתך רוחב | מִשׁקָל | מודול חתך אלסטי | רגע האינרציה | שטח ציפוי (שני הצדדים לכל ערימה) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (ח) | אוגן (tf) | אינטרנט (tw) | לכל ערימה | לכל קיר | |||||

| mm | mm | mm | mm | סמ"ר/מ"ר | ק"ג/מ"ר | ק"ג/מ"ר | סמ"ק/מ"ר | סמ"ק/מ"ר | מ"ר/מ"ר | |

| CRZ12-700 | 700 | 440 | 6 | 6 | 89.9 | 49.52 | 70.6 | 1,187 | 26,124 | 2.11 |

| CRZ13-670 | 670 | 303 | 9.5 | 9.5 | 139 | 73.1 | 109.1 | 1,305 | 19,776 | 1.98 |

| CRZ13-770 | 770 | 344 | 8.5 | 8.5 | 120.4 | 72.75 | 94.5 | 1,311 | 22,747 | 2.2 |

| CRZ14-670 | 670 | 304 | 10.5 | 10.5 | 154.9 | 81.49 | 121.6 | 1,391 | 21,148 | 2 |

| CRZ14-650 | 650 | 320 | 8 | 8 | 125.7 | 64.11 | 98.6 | 1,402 | 22,431 | 2.06 |

| CRZ14-770 | 770 | 345 | 10 | 10 | 138.5 | 83.74 | 108.8 | 1,417 | 24,443 | 2.15 |

| CRZ15-750 | 750 | 470 | 7.75 | 7.75 | 112.5 | 66.25 | 88.34 | 1,523 | 35,753 | 2.19 |

| CRZ16-700 | 700 | 470 | 7 | 7 | 110.4 | 60.68 | 86.7 | 1,604 | 37,684 | 2.22 |

| CRZ17-700 | 700 | 420 | 8.5 | 8.5 | 132.1 | 72.57 | 103.7 | 1,729 | 36,439 | 2.19 |

| CRZ18-630 | 630 | 380 | 9.5 | 9.5 | 152.1 | 75.24 | 119.4 | 1,797 | 34,135 | 2.04 |

| CRZ18-700 | 700 | 420 | 9 | 9 | 139.3 | 76.55 | 109.4 | 1,822 | 38,480 | 2.19 |

| CRZ18-630N | 630 | 450 | 8 | 8 | 132.7 | 65.63 | 104.2 | 1,839 | 41,388 | 2.11 |

| CRZ18-800 | 800 | 500 | 8.5 | 8.5 | 127.2 | 79.9 | 99.8 | 1,858 | 46,474 | 2.39 |

| CRZ19-700 | 700 | 421 | 9.5 | 9.5 | 146.3 | 80.37 | 114.8 | 1,870 | 39,419 | 2.18 |

| CRZ20-700 | 700 | 421 | 10 | 10 | 153.6 | 84.41 | 120.6 | 1,946 | 40,954 | 2.17 |

| CRZ20-800 | 800 | 490 | 9.5 | 9.5 | 141.2 | 88.7 | 110.8 | 2,000 | 49,026 | 2.38 |

גובה (H) של יריעות פלדה בצורת Z נע בדרך כלל בין 200 מ"מ ל-600 מ"מ.

הרוחב (B) של יריעות פלדה בצורת Z מדגם Q235b נע בדרך כלל בין 60 מ"מ ל-210 מ"מ.

העובי (t) של יריעות פלדה בצורת Z נע בדרך כלל בין 6 מ"מ ל-20 מ"מ.

*שלחו את המייל אל[מוגן בדוא"ל]לקבלת הצעת מחיר לפרויקטים שלך

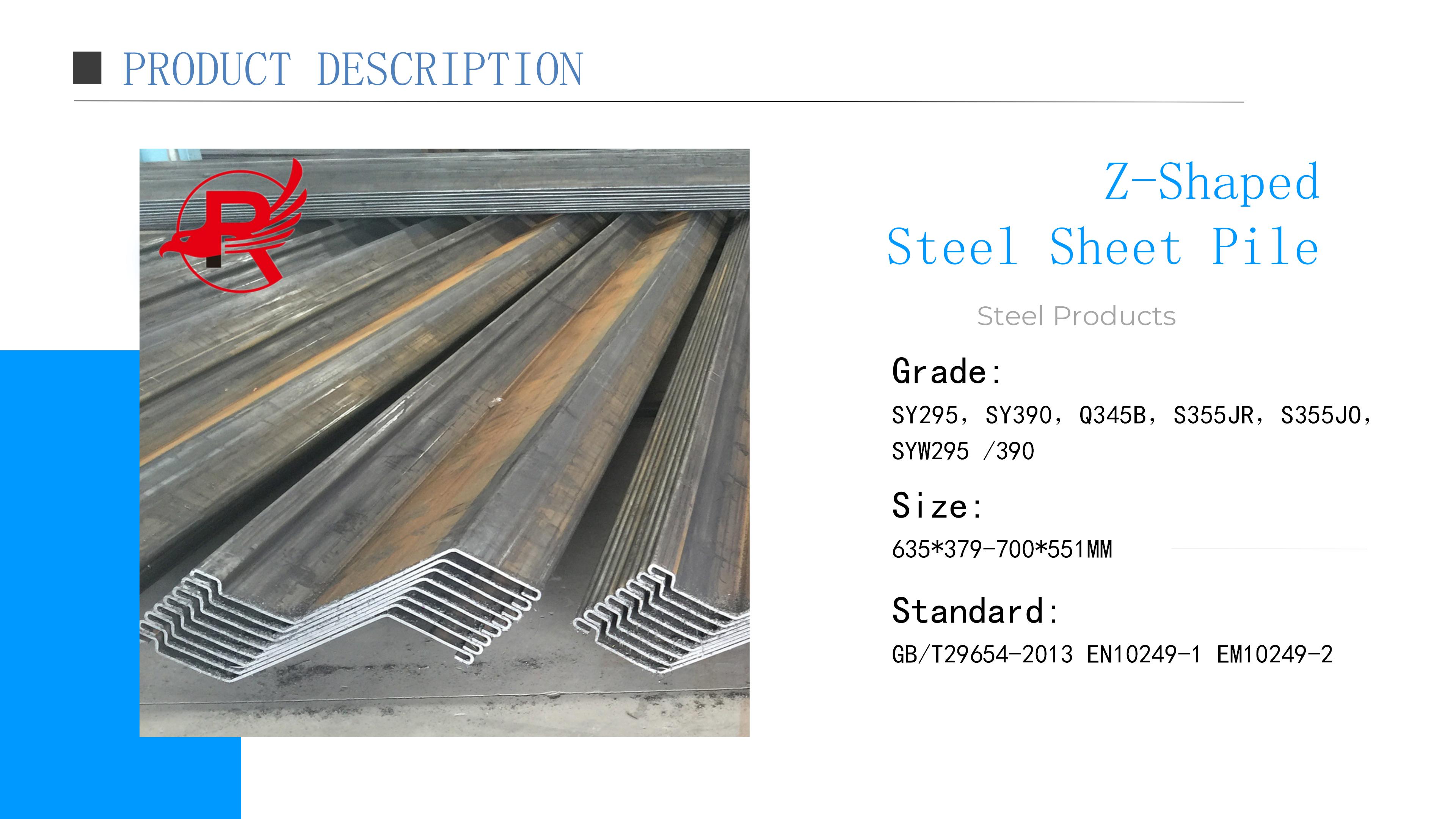

תיאור המוצר

| שם המוצר | |||

| MOQ | 25 טון | ||

| תֶקֶן | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN וכו'. | ||

| מֶשֶׁך | 1-12 מטר או לפי הדרישה שלך | ||

| רוֹחַב | 20-2500 מ"מ או לפי הדרישה שלך | ||

| עוֹבִי | 0.5 - 30 מ"מ או לפי הדרישה שלך | ||

| טֶכנִיקָה | מגולגל חם או מגולגל קר | ||

| טיפול פני השטח | ניקוי, ניקוי וצביעה לפי דרישות הלקוח | ||

| סובלנות עובי | ±0.1 מ"מ | ||

| חוֹמֶר | Q195; Q235(A,B,C,DR); Q345(B,C,DR); Q345QC Q345QD SPCC SPCD SPCD SPCE ST37 ST12 ST15 DC01 DC02 DC03 DC04 DC05 DC06 20#- 35# 45# 50#, 16Mn-50Mn 30Mn2-50Mn2 20Cr, 20Cr, 40Cr 20CrMnTi 20CrMo;15CrMo;30CrMo 35CrMo 42CrMo; 42CrMo4 60Si2mn 65mn 27SiMn ;20Mn; 40Mn2; 50Mn; 1cr13 2cr13 3cr13 -4Cr13; | ||

| בַּקָשָׁה | הוא נמצא בשימוש נרחב בכלים קטנים, רכיבים קטנים, חוט ברזל, סידרוספירה, מוט משיכה, טבעת הידוק, הרכבת ריתוך, מתכת מבנית, מוט חיבור, וו הרמה, בורג, אום, ציר, מנדריל, סרן, גלגל שרשרת, גלגל שיניים, מצמד לרכב. | ||

| אריזת יצוא | נייר עמיד למים, ורצועת פלדה ארוזים. חבילה סטנדרטית ליצוא כשירה לשיט. מתאים לכל סוגי ההובלה, או לפי הצורך | ||

| בַּקָשָׁה | בניית ספינות, לוח פלדה ימי | ||

| תעודות | ISO, CE | ||

| זמן אספקה | בדרך כלל תוך 10-15 ימים לאחר קבלת תשלום מראש | ||

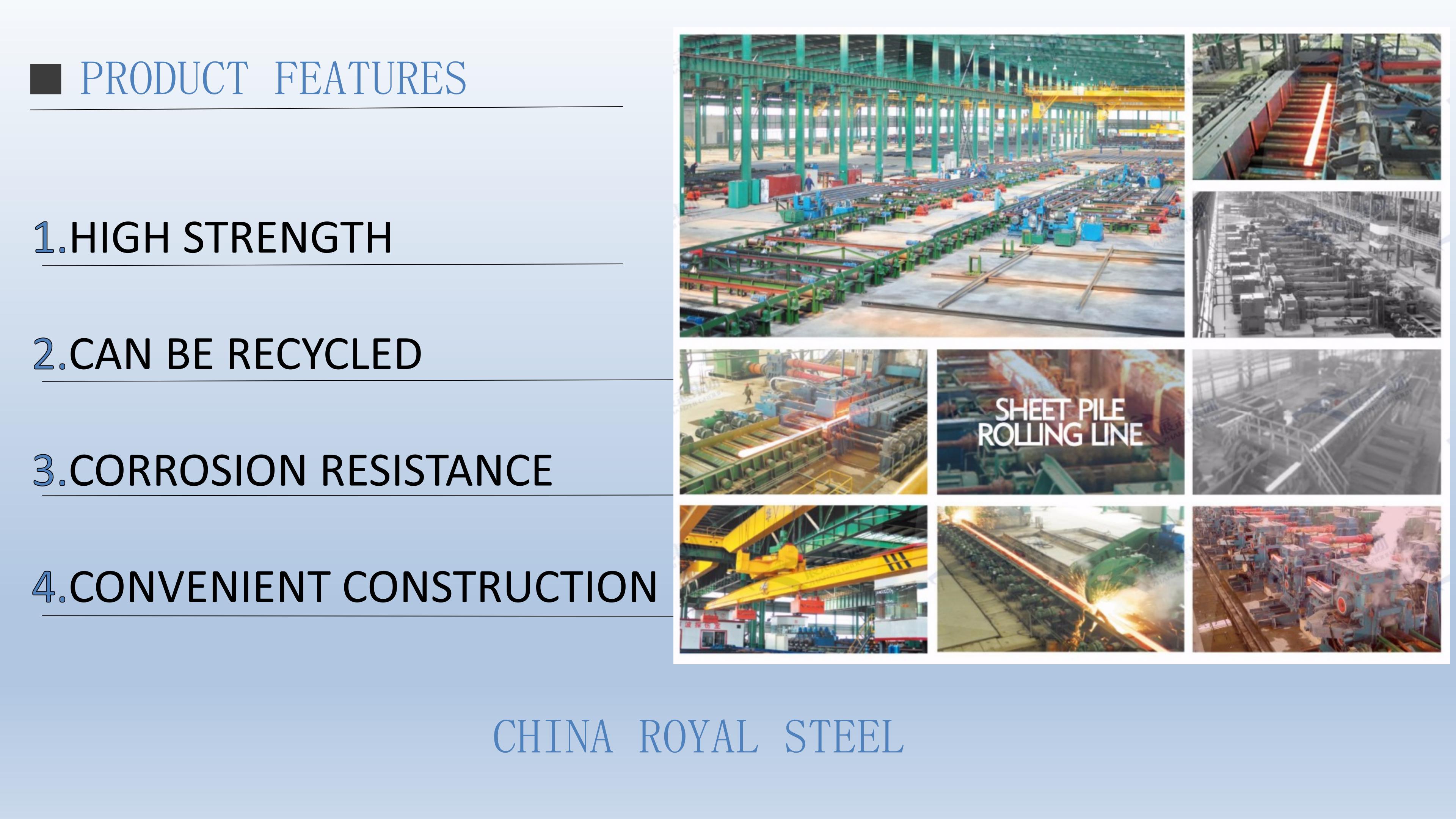

תכונות

יריעות פלדה Z, הידועות גם כיריעות בצורת Z או פרופילי Z, משמשות בדרך כלל בפרויקטים שונים של בנייה ותשתיות. להלן מספר מאפיינים של יריעות פלדה Z:

צוּרָה:יריעות פלדה Zבעלי חתך רוחב ייחודי בצורת Z. צורה זו מספקת חוזק מבני ויציבות מצוינים, מה שהופך אותם למתאימים ליישומים שונים, כולל קירות תמך, סכרים, הגנה מפני הצפות וחפירות עמוקות.

עיצוב משולב: יריעות פלדה Z כוללות מנגנוני חיבור משני הצדדים, המאפשרים חיבור חלק של כלונסאות. עיצוב משולב זה מספק חיבור קשיח ואטום למים בין כלונסאות בודדות, תוך הבטחת יציבות ומונע חדירת מים.

חוזק גבוה: יריעות פלדה Z מיוצרות מפלדה איכותית, המציעה חוזק ועמידות יוצאי דופן. זה מאפשר להן לעמוד בעומסים כבדים, להתנגד לעיוות ולעמוד בתנאי סביבה קשים.

רב-תכליתיות:יריעות פלדה Zמגיעים בגדלים ובחוזקות שונים, מה שמאפשר גמישות בתכנון וביישום. ניתן להשתמש בהם הן במבנים זמניים והן במבנים קבועים, והאופי המודולרי שלהם הופך אותם למתאימים לדרישות פרויקטים שונות.

התקנה קלה: יריעות פלדה Z מתוכננות להתקנה מהירה ויעילה. ניתן להכניס אותן לקרקע באמצעות פטישי רטט או מכבשים הידראוליים, מה שמפחית את הזמן והעבודה הנדרשים להתקנה.

חסכון: יריעות פלדה Z מציעות פתרון חסכוני לבניית קירות תמך ומבנים דומים. חוזקן הגבוה וחיי השירות הארוכים שלהם מפחיתים את הצורך בהחלפות או תיקונים תכופים, וכתוצאה מכך חיסכון בעלויות לאורך חיי הפרויקט.

יתרונות סביבתיים: יריעות פלדה Z הן בחירה בת קיימא מכיוון שניתן למחזר אותן ולעשות בהן שימוש חוזר לאחר חיי השירות שלהן. בנוסף, השימוש בהן במבני תמך יכול למזער את השימוש בקרקע ולהפחית את ההשפעה על הסביבה.

בַּקָשָׁה

למערכות יריעות פלדה Z מגוון רחב של יישומים בהנדסה אזרחית ובבנייה. כמה יישומים נפוצים כוללים:

- קירות תמך:יריעות פלדה Z משמשות בדרך כלל בבניית קירות תמך לייצוב ולתמוך בקרקע או בחומרים אחרים בגבהים שונים. הן מספקות מחסום בטוח מפני סחף קרקע ולחץ רוחבי, תוך מתן אפשרות להתקנה והסרה יעילות במידת הצורך.

- קופרדאמים:יריעות פלדה Z משמשות לעתים קרובות ליצירת קופר-סכרים זמניים עבור פרויקטים של בנייה בגופי מים. העיצוב המשולב של הציר מבטיח אטימה למים, המאפשרת ייבוש מים ומאפשרת ביצוע פעילויות בנייה באזור עבודה יבש.

- חפירות עמוקות:יריעות פלדה Z משמשות לתמיכה בחפירות עמוקות, כגון לבניית מרתפים או מבנים תת-קרקעיים. הן מספקות יציבות מבנית, מונעות תזוזת קרקע ומשמשות כמחסום מגן מפני חלחול מים לאזור החפירה.

- הגנה מפני שיטפונות:יריעות פלדה Z משמשות לעתים קרובות במערכות הגנה מפני שיטפונות לחיזוק ואבטחת גדות נהרות, סכרים ומבנים אחרים למניעת שיטפונות. חוזקן ואטימותם של הצירים מסייעים להתנגד לכוחות המופעלים על ידי מים, מונעים סחף ומבטיחים את שלמות אמצעי בקרת השיטפונות.

- מבני קו המים:יריעות פלדה Z משמשות בדרך כלל בבניית קירות רציף, רציפים, מרינות ומבנים אחרים על קו המים. היריעות מספקות יציבות ותמיכה, ומאפשרות הפעלה בטוחה ויעילה של כלי שיט ומתקני נמל.

- תמך הגשר:יריעות פלדה Z משמשות בבניית גשרים כתומכים, המספקות תמיכה ויציבות ליסודות הגשר.

- ייצוב קרקע ומדרון:יריעות פלדה Z משמשות לייצוב קרקע ומדרונות, במיוחד באזורים הנוטים למפולות או סחף. הן יכולות לסייע במניעת תזוזת קרקע ולספק יציבות לסוללות, מורדות גבעות ומדרונות אחרים.

![0$NU_O5TD8Y4}`E3UXEVP]2](http://www.chinaroyalsteel.com/uploads/0NU_O5TD8Y4E3UXEVP2.jpg)

אריזה ומשלוח

אריזה:

ערמו את יריעות הבנייה בצורה בטוחה: סדרו את יריעות הבנייה בצורת Z בערימה מסודרת ויציבה, וודאו שהן מיושרות כראוי כדי למנוע חוסר יציבות. השתמשו ברצועות או פסי קשירה כדי לאבטח את הערימה ולמנוע תזוזת בנייה במהלך ההובלה.

השתמשו בחומרי אריזה מגנים: עטפו את ערימת יריעות הבנייה בחומר עמיד בפני לחות, כגון פלסטיק או נייר עמיד למים, כדי להגן עליהן מחשיפה למים, לחות ואלמנטים סביבתיים אחרים. זה יסייע במניעת חלודה וקורוזיה.

מִשׁלוֹחַ:

בחירת אמצעי תחבורה מתאים: בהתאם לכמות ומשקל יריעות הנייר, בחרו את אמצעי התחבורה המתאים, כגון משאיות שטוחות, מכולות או ספינות. יש לקחת בחשבון גורמים כמו מרחק, זמן, עלות וכל דרישות רגולטוריות להובלה.

השתמשו בציוד הרמה מתאים: כדי להעמיס ולפרוק את יריעות הפלדה בצורת U, השתמשו בציוד הרמה מתאים כגון מנופים, מלגזות או מעמיסים. ודאו שלציוד בו נעשה שימוש יש קיבולת מספקת כדי להתמודד עם משקל יריעות הפלדה בבטחה.

אבטחת המטען: אבטחו כראוי את ערימת יריעות הנייר הארוזות על רכב ההובלה באמצעות רצועות, חיזוק או אמצעים מתאימים אחרים כדי למנוע תזוזה, החלקה או נפילה במהלך ההובלה.

תהליך ייצור המוצר

תהליך הייצור של יריעות פלדה בצורת Z בעיצוב קר כולל בדרך כלל את השלבים הבאים:

הכנת חומרים: בחירת חומרי פלדה העומדים בדרישות, בדרך כלל פלדות פלדה מגולגלות בחום או בקור, ובחירת חומרים בהתאם לדרישות התכנון והתקנים.

חיתוך: חיתוך לוח הפלדה בהתאם לדרישות התכנון כדי לקבל ריק של לוח פלדה העומד בדרישות האורך.

כיפוף קר: חתיכת לוח הפלדה הגולמית נשלחת למכונת כיפוף קר לצורך עיבוד עיצוב. לוח הפלדה מכופף בקור לחתך רוחב בצורת Z באמצעות תהליכים כמו גלגול וכיפוף.

ריתוך: ריתוך קירות הפלדה בצורת Z שעברו עיבוד קר כדי להבטיח שהחיבורים שלהם יציבים וללא פגמים.

טיפול פני השטח: טיפול פני השטח מבוצע על יריעות פלדה מרותכות בצורת Z, כגון הסרת חלודה, צביעה וכו', כדי לשפר את ביצועיהן נגד קורוזיה.

בדיקה: ביצוע בדיקת איכות על יריעות פלדה בצורת Z המיוצרות בעיצוב קר, כולל בדיקת איכות המראה, סטייה ממדית, איכות ריתוך וכו'.

אריזה ועזיבת המפעל: יריעות הפלדה בצורת Z המעוצבות בקור ארוזות, מסומנות במידע על המוצר ונשלחות מהמפעל לאחסון.

*שלחו את המייל אל[מוגן בדוא"ל]לקבלת הצעת מחיר לפרויקטים שלך

תהליך ביקור הלקוח

כאשר לקוח מעוניין לבקר במוצר, בדרך כלל ניתן לתאם את השלבים הבאים:

קביעת פגישה לביקור: לקוחות יכולים ליצור קשר עם היצרן או נציג המכירות מראש כדי לקבוע פגישה לגבי הזמן והמקום לביקור במוצר.

ארגון סיור מודרך: הזמנת אנשי מקצוע או נציגי מכירות כמדריכי טיולים כדי להראות ללקוחות את תהליך הייצור, הטכנולוגיה ותהליך בקרת האיכות של המוצר.

הצגת מוצרים: במהלך הביקור, הציגו מוצרים בשלבים שונים ללקוחות כדי שהלקוחות יוכלו להבין את תהליך הייצור ואת תקני האיכות של המוצרים.

מענה לשאלות: במהלך הביקור, ללקוחות עשויות להיות שאלות שונות, ועל מדריך הטיולים או נציג המכירות לענות עליהן בסבלנות ולספק מידע טכני ואיכותי רלוונטי.

ספקו דוגמיות: במידת האפשר, ניתן לספק ללקוחות דוגמיות מוצר כדי שיוכלו להבין בצורה אינטואיטיבית יותר את איכות המוצר ומאפייניו.

מעקב: לאחר הביקור, יש לעקוב באופן מיידי אחר משוב הלקוחות וצרכיו כדי לספק ללקוחות תמיכה ושירותים נוספים.

כאשר לקוח מעוניין לבקר במוצר, בדרך כלל ניתן לתאם את השלבים הבאים:

קביעת פגישה לביקור: לקוחות יכולים ליצור קשר עם היצרן או נציג המכירות מראש כדי לקבוע פגישה לגבי הזמן והמקום לביקור במוצר.

ארגון סיור מודרך: הזמנת אנשי מקצוע או נציגי מכירות כמדריכי טיולים כדי להראות ללקוחות את תהליך הייצור, הטכנולוגיה ותהליך בקרת האיכות של המוצר.

הצגת מוצרים: במהלך הביקור, הציגו מוצרים בשלבים שונים ללקוחות כדי שהלקוחות יוכלו להבין את תהליך הייצור ואת תקני האיכות של המוצרים.

מענה לשאלות: במהלך הביקור, ללקוחות עשויות להיות שאלות שונות, ועל מדריך הטיולים או נציג המכירות לענות עליהן בסבלנות ולספק מידע טכני ואיכותי רלוונטי.

ספקו דוגמיות: במידת האפשר, ניתן לספק ללקוחות דוגמיות מוצר כדי שיוכלו להבין בצורה אינטואיטיבית יותר את איכות המוצר ומאפייניו.

מעקב: לאחר הביקור, יש לעקוב באופן מיידי אחר משוב הלקוחות וצרכיו כדי לספק ללקוחות תמיכה ושירותים נוספים.

שאלות נפוצות

ש: האם אתה חברת סחר או יצרן?

א: אנחנו יצרן, עם מחסן משלו וחברת מסחר.

ש: כמה זמן הוא זמן האספקה שלך?

א: בדרך כלל זה 5-10 ימים אם הסחורה במלאי. או 15-20 ימים אם הסחורה אינה במלאי, בהתאם לכמות ההזמנה.

ש: האם אתם מספקים דוגמיות? האם זה בחינם או בתשלום נוסף?

ת: כן, אנו מספקים את המדגם בחינם, הלקוח משלם דמי משלוח.

ש: מה לגבי ה-MOQ שלך?

א: טון אחד מקובל, 3-5 טון למוצר מותאם אישית.